2 5 metal lath galvanized a multi purpose utility lath base suitable for a multi purpose utility lath base suitable for use with either steel or wood framing.

Nailing pattern for metal lath. Stagger the joints of lath on the surface similar to a brick pattern therefore staggering the vertical butt joints. Sheets shall be installed perpendicular to the vertical framing lapping the lath 1 at the edges. On vertical applications nails shall be bent over to engage at least 3 strands over and through rib on rib lath and bridge ribs with staples. Appropriately the measure of an expanded metal lath product s quality begins during the manufacturing process.

Manufacturing to astm specifications. Walls and ceilings that use metal lath for the plaster base should be divided into rectangular panels with control joint at least every 18 feet or at the juncture of a dissimilar wall or in either direction in a length to width ratio of 2 to 1 or in ceilings exceeding 100 sq. Install rib metal lath with ribs against the supports see illustra tion attach metal lath to supports not to exceed 7 in. And astm c1063 standard specification for installation of lathing and furring to receive interior and exterior portland cement based plaster.

The following are the eight deadly sins of metal lath installation for portland cement stucco. Attach metal lath sheets to the substrate beginning at the base of the wall and working up the wall. On center along all supports. And if you ve ever had to deal with a home inspector checking your nailing schedule then you probably know all about how big of a pain in the a it can be to make them happy.

To the proper installation of metal lath and portland cement stucco including those that are most often overlooked or improperly performed. Will allow it but it is more expensive than traditional wire and most people won t use it because of that reason. Nailing methods on horizontal applications all nails shall be driven flush with base driven home. Improper plywood sheathing installation not necessarily the responsibility of the lathing con tractor.

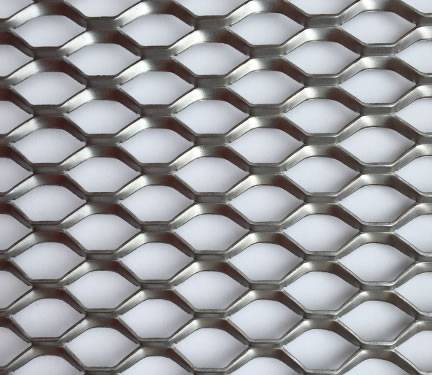

Or walls exceeding 144 feet in area. Expanded metal lath is formed from sheet steel that has been slit and expanded to form thousands of keys per square yard. This particular lath has a much smaller pattern in the wire itself. Lath fasteners to concrete.

It is an excellent base for stone spray on structural fireproofing ornamental work and under ceramic tile. It is easily cut and formed to accommodate curved surfaces and is commonly used for external stucco applications. The flat surface is easily cut and formed for use with flat or contoured surfaces. Use 3 8 diameter shank 3 4 in length.

Wire tie metal lath at the side laps with single loop of 0 043 in. It allows the cement to bond to it very well and is usually used for patches transitions and uneven surfaces.